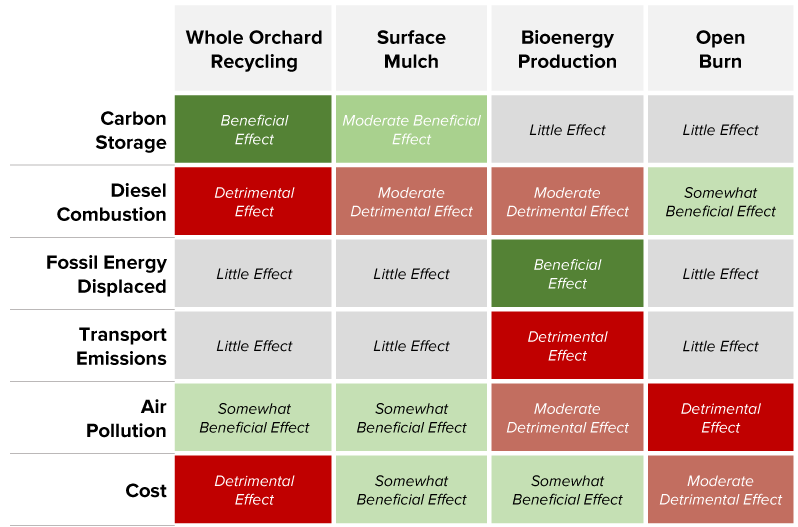

The amount of woodchip biomass added to the soil after whole orchard recycling (WOR) holds great potential to increase carbon storage in the form of soil organic matter. However, it also requires a lot of diesel-burning equipment to make it happen. From the perspective of net emissions of greenhouse gases and other types of pollutants, how does WOR compare to other options for managing end-of-life tree biomass, such as burning or sending wood chips to biomass power plants?

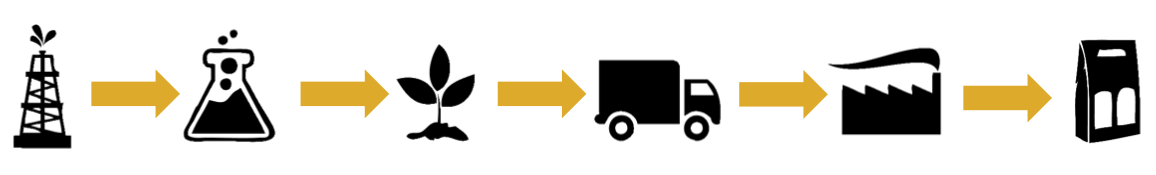

Answering this question requires researchers to use a method known as life cycle assessment (LCA) to estimate the environmental impacts and resources used throughout a product's life, from raw materials extraction to production, and extending through product use and disposal.

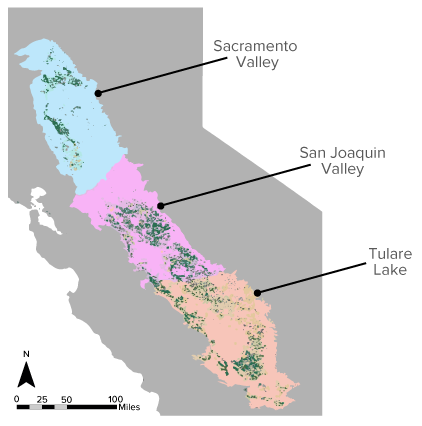

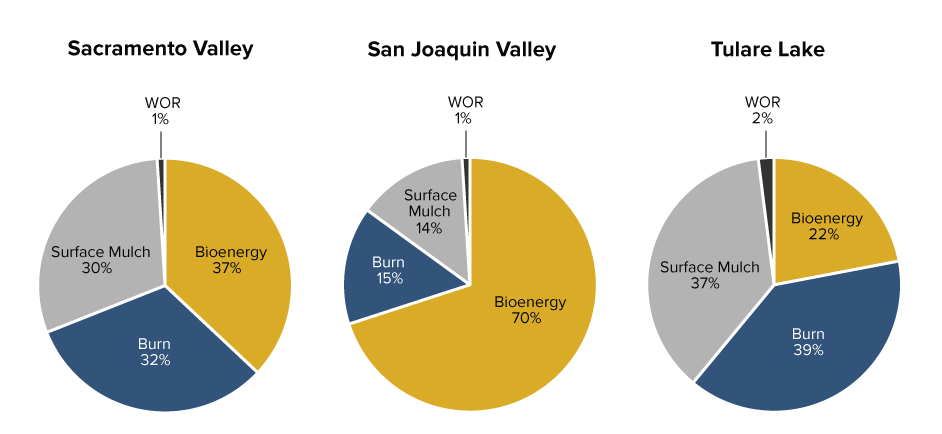

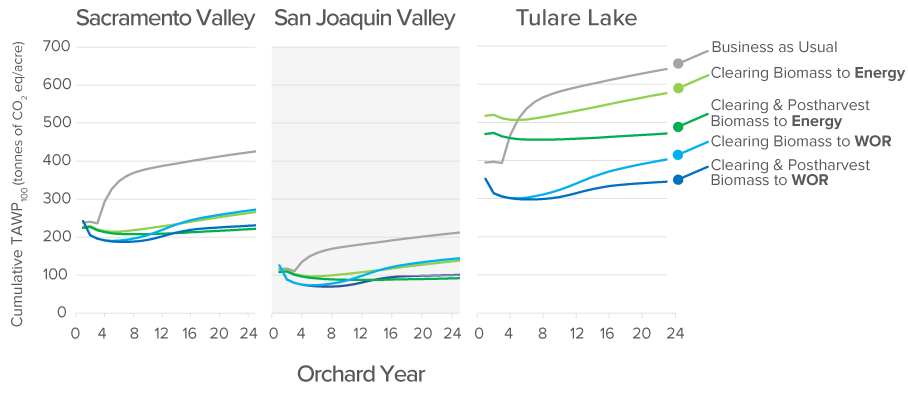

UC Davis researchers used this method to assess the net greenhouse gas emissions and other air and water pollutants arising from the production and use of all materials and energy sources typically required for almond production in California over the orchard lifespan, typically 23–25 years. The researchers compared the net greenhouse gas and pollutant emissions from WOR, surface mulching, in-field burning, and sending wood chips to power generation. Here we focus on the greenhouse gas emissions.